Rotary Dryer

Rotary Kiln

Ball Mill

Trapezium Grinding Mill

Ribbon Blender

Pneumatic Dust Collector

Biomass Crusher

Impact Crusher

Sand Washer

Welcome to

Sri Sai Heavy Machineries

Please click the link

on the left pan....

Sri Sai Heavy Machineries

Please click the link

on the left pan....

‘SSHM’ Rotary dryer’s are mainly used for drying materials with some moisture and granularity in ore beneficiation, building material, metallurgy and chemical industries. Rotary dryer has high adaptability to the materials so that it can be used for drying all kinds of materials, and in addition, the operation of this equipment is simple and reliable, for this reason, it gets wide application.

It also has a high degree of mechanization, larger production capacity and continuous operation. Structure was simple and excellent,Low malfunction, lower maintenance cost & low power consumption.

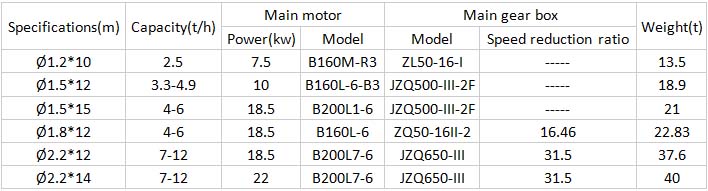

Specifications:

It also has a high degree of mechanization, larger production capacity and continuous operation. Structure was simple and excellent,Low malfunction, lower maintenance cost & low power consumption.

Specifications:

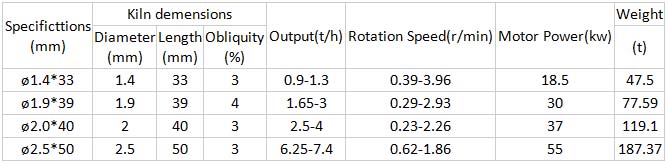

‘SSHM’ Rotary kiln refers to rotary calcining kiln (commonly known as rotary kiln) which belongs to material building equipment. Rotary kiln according to processing different materials can be divided into cement kiln, metallurgy chemical kiln and lime kiln. Cement kiln is the major equipment of dry and wet cement clinker production lines. The rotary kiln composed by the cylinder, bearing devices, devices with a gear wheel bearing, gear, activities, kiln, kiln seals, coal burner unit and other components.

Specifications:

Specifications:

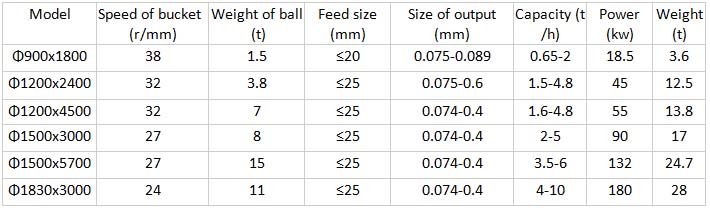

‘SSHM’ Ball mill is a principle and cylindrical revolving device belongs to external gear-driving ball mill. The materials are transported by feeder, and gets into mill chamber through hollow screw axis equably, and there is lining plate and steel balls provided inside the chamber. When the cylinder body goes round and round, the steel ball is taken to certain height and then falls down, and the materials are struck and grinded heavily. The above action repeats constantly till the size of materials reaches the required fineness. The powdery materials are discharged through discharge grate plate, and the milling work is over.

Specifications:

Specifications:

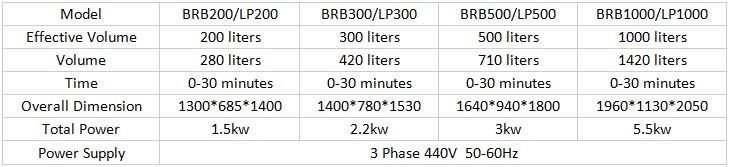

‘SSHM’ Ribbon mixer cum blender is characterized by high mixing precision, and wide application to food, chemical industries, and building lines. The major sections of a mixer are barrel, ribbon agitators, feeding ports, discharging port and driven unit!!

Double ribbon mixer drive the material from two ends to centre through the help of the outer ribbon, while the inner ribbon push the material from centre to two ends, thus, material achieve a high mixing effect at short time.Our ribbon mixer can be equipped with heating or cooling jacket if temperature control is required.

Double ribbon mixer drive the material from two ends to centre through the help of the outer ribbon, while the inner ribbon push the material from centre to two ends, thus, material achieve a high mixing effect at short time.Our ribbon mixer can be equipped with heating or cooling jacket if temperature control is required.

‘SSHM’ Pulse Jet Hose Bag Type Filters are commonly known as conventional filters. We have developed new age designs for this filters which gives better life of filter bags, Lower emission levels, Lower Pressure drops, lower power consumption, Higher air to Cloth Ratios with better performance levels, Lower Floor Space Requirement With Higher Air To Cloth Ratios. SSHM supplies customized bag filters on the bases of application requirement. These Pulse Jet Bag Filters are used where airflows are in large quantity, temperatures are higher than ambient or material to be handled is difficult.

Following are the features of SSHM Pulse Jet Bag Filter:

Modular Designs Available starting from 1600 m3/hr to 4,00,000 m3/hr

Tool less installation/replacement of bag & Cages

Variety of Filter media available for different applications

Easy to Install & Commission

Following are the major materials handled by ‘SSHM’ Dust Collector:

Alumina, Ash, Bag House Dust, Barlite, Bentonite, Carbon Black, Cement, Clay, Calcium Carbonate, Cornstarch, Cement Clinker, Diatomaceous Earth, Flyash, Flour, Fluorspar, Gypsum, Lime, Perlite, PVC Resin, Salt, Sand, Soda Ash, Soap Powder, Talc, Food Powder, Master batch, Carbon Black Application, Cement Industry, Foundry, Power, Plastic, Soap & Detergent, Foundry Sand, Manganese Ore, Silica, Furnace Fumes & Dust, Boiler Fly Ash, Welding Fumes and many more…

Following are the features of SSHM Pulse Jet Bag Filter:

Modular Designs Available starting from 1600 m3/hr to 4,00,000 m3/hr

Tool less installation/replacement of bag & Cages

Variety of Filter media available for different applications

Easy to Install & Commission

Following are the major materials handled by ‘SSHM’ Dust Collector:

Alumina, Ash, Bag House Dust, Barlite, Bentonite, Carbon Black, Cement, Clay, Calcium Carbonate, Cornstarch, Cement Clinker, Diatomaceous Earth, Flyash, Flour, Fluorspar, Gypsum, Lime, Perlite, PVC Resin, Salt, Sand, Soda Ash, Soap Powder, Talc, Food Powder, Master batch, Carbon Black Application, Cement Industry, Foundry, Power, Plastic, Soap & Detergent, Foundry Sand, Manganese Ore, Silica, Furnace Fumes & Dust, Boiler Fly Ash, Welding Fumes and many more…

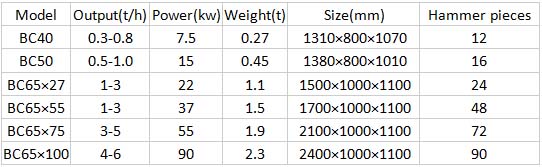

We are the professional manufacturer & offer ‘SSHM’ biomass crusher with more than 50 years of manufacturing experience.More than 70% of our machines are exported to other countries annually.

They are the most ideal grinding equipments of all kinds of stalk, weed, corn, soybean, PVC foaming board, rubber, and etc.Its structure reasonable, firm durable, safe reliable, easy operation, the vibration small, and the efficiency is high.

Applications:

This biomass crusher is widely used in the professions such as fodder factory, cultivation factory, organic fertilizer factory, medicine & chemical industry and so on.

They are the most ideal grinding equipments of all kinds of stalk, weed, corn, soybean, PVC foaming board, rubber, and etc.Its structure reasonable, firm durable, safe reliable, easy operation, the vibration small, and the efficiency is high.

Applications:

This biomass crusher is widely used in the professions such as fodder factory, cultivation factory, organic fertilizer factory, medicine & chemical industry and so on.

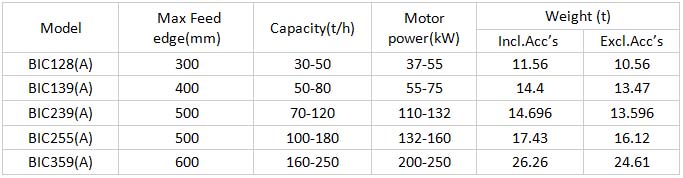

‘SSHM’ Impact Crusher’s are built on advanced technology with a combination of domestic applications. More human-oriented with simple design and reasonable structure, bigger and better cavity, higher capacity. Our Impact Crusher can crush all kinds of soft and medium-hard ore, for coarse, medium and fine crushing, in primary and secondary crushing process. The series can be widely used in mining, construction, chemical, cement, metallurgical, etc. industries.

‘SSHM’ sand washer is a kind of highly-efficient sand washing equipment, combining the advanced techniques and the domestic physical conditions of sand industry.Sand washing machine is sand washing plant, mainly used for removing dust in the ore. Impurity and dust are removed in the artificial sand production process. According to its shape, sand washing machine can be divided into spiral sand washing machine and bucket sand washer. The sand washing machine has the advantages of high cleanliness, reasonable structure and high productivity.

During the washing process, little sand runs off. The transmission part is separated from the water and the fault rate of the sand washing machine is further lower than the commonly used sand washing machine, making the best upgraded equipment in the sand washing machine.The sand washer features in high efficiency and low energy consumption.

During the washing process, little sand runs off. The transmission part is separated from the water and the fault rate of the sand washing machine is further lower than the commonly used sand washing machine, making the best upgraded equipment in the sand washing machine.The sand washer features in high efficiency and low energy consumption.

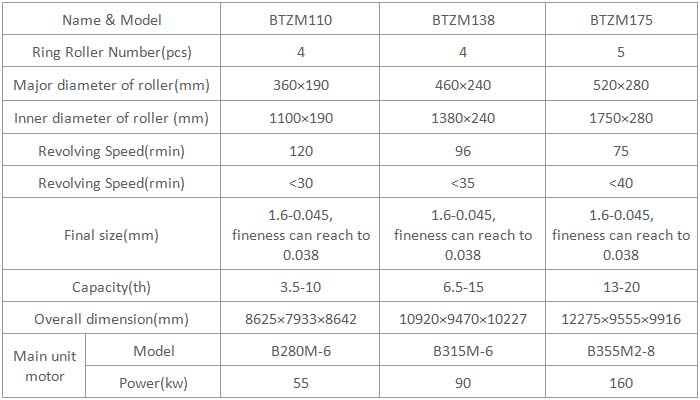

‘SSHM’ Trapezium stone grinding mill is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite,barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassiumore pumice, etc.